Properties

Spider

silk is incredibly tough and is stronger by weight than steel.

Quantitatively, spider silk is five times stronger than steel of the same

diameter. It has been suggested that a Boeing 747 could be stopped in

flight by a single pencil-width strand and spider silk is almost as strong as

Kevlar, the toughest man-made polymer. It is finer than the human hair

(most threads are a few microns in diameter) and is able to keep its strength

below -40°C. The toughest silk is the dragline silk from the Golden

Orb-Weaving spider (Nephilia clavipes), so-called

because it uses silk of a golden hue to make orb webs.

Spider silk is also very elastic and capture silk (sticky silk for catching prey) remains unbroken after being stretched 2-4 times its original length. Spider silk is tougher, more elastic and more waterproof than silkworm silk so it could have a much wider range of applications. It is simple to see why spider silk is of such interest to materials chemists since new ultra-strong fibres based on the silk could be developed.

Uses

Uses

Spiders use silk for a variety of functions:

Swathing silk for the wrapping and immobilisation of prey.

Webs

for catching prey using sticky silk - it is elastic to prevent the prey from

rebounding off the web.

Draglines which are used to connect the spider to the web, as safety lines in case a spider should fall and as the non-sticky spokes of the web. Dragline silk is the strongest kind of silk because it must support the weight of the spider.

Parachuting or ballooning which is used to aid the dispersal of young and to find new areas as a food source. Silk is released and is caught by the wind to lift the spider up into the air - flying spiders!

Shelters such as burrows or nests

Egg-sacs

Mating: male spiders weave sperm webs on which they deposit sperm and subsequently transfer it to their front palps, ready for placing on a females genital organs. Some species make a web and coat it with sex pheromones to attract a mate.

Production

There are seven types of silk produced by seven silk glands. A single spider does not possess all seven glands but has at least three if it is male (dragline, attachment and swathing silk) or four if it is female. The additional one is for egg sac silk. The seven types of gland are:

Achniform gland: swathing silk.

Cylindriform gland: egg sac silk.

Ampullate glands (major and minor): non-sticky dragline silk. Silk from the minor ampullate gland is only half as strong as that from the major gland.

Pyriform gland: attaching threads - attachment discs are made which anchor a thread to a surface or another thread.

Flagelliform gland: core fibres of sticky silk.

Aggregate gland: outer part of sticky silk - droplets of an adhesive substance are deposited along the threads.

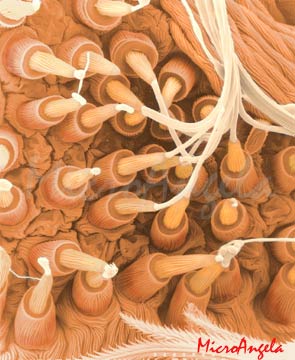

Courtesy of Tina Carvlho, Microangela

The glands are located on the lower side of the abdomen (see diagram below) and contain a watery fluid known as 'dope'. This fluid passes through to the spinneret via a multitude of microscopic tubes where water recovery and solidification begins. Fluid from different glands can lead to the same spinneret so silk with specific properties required for a particular function can be produced. There are usually three pairs of spinnerets but this can vary between 1 and 4 pairs depending on the species. The substance exits through the spiggots which are mobile, finger-like protrusions and the resulting silk emerges as a solid. There are many spigots so many fibres are bound together like a cable. The diameter of a single fibre is controlled by the muscular action of a valve. The faster and tighter the strand is drawn, the stronger the silk.

Picture from reference 11

Some interesting web facts:

Not all spiders weave webs.

Spiders do not stick to their own web because only the central spiral part of the web is sticky, not the spokes. The spider knows where to tread!

Webs lose their stickiness after about a day due to factors such as dust accumulation and exposure to air. In order to save energy the spider eats its own web before making a new one so the protein used for the silk threads is recycled.