Applications of Spider Silk

Humans have been making use of spider silk for thousands of years. The ancient Greeks used cobwebs to stop wounds from bleeding and the Aborigines used silk as fishing lines for small fish. More recently, silk was used as the crosshairs in optical targeting devices such as guns and telescopes until World War II and people of the Solomon Islands still use silk as fish nets.

Current

research in spider silk involves its potential use as an incredibly strong and

versatile material. The interest in

spider silk is mainly due to a combination of its mechanical properties and the

non-polluting way in which it is made. The

production of modern man-made super-fibres such as Kevlar involves petrochemical

processing which contributes to pollution.

Kevlar is also drawn from concentrated sulphuric acid.

In contrast, the production of spider silk is completely environmentally

friendly. It is made by spiders at

ambient temperature and pressure and is drawn from water.

In addition, silk is completely biodegradable. If the production of spider silk ever becomes industrially

viable, it could replace Kevlar and be used to make a diverse range of items

such as:

Bullet-proof clothing

Wear-resistant lightweight clothing

Ropes, nets,

seat belts, parachutes

Rust-free panels on motor vehicles or boats

Biodegradable bottles

Bandages, surgical thread

Artificial tendons or ligaments, supports for weak blood vessels.

However the production of spider silk is not simple and there are inherent problems. Firstly spiders cannot be farmed like silkworms since they are cannibals and will simply eat each other if in close proximity. The silk produced is very fine so 400 spiders would be needed to produce only one square yard of cloth. The silk also hardens when exposed to air which makes it difficult to work with.

The

alternative approach is to learn how spiders spin silk and then copy them to

make synthetic spider silk. The

silk itself would also have to be artificially made.

Chemical synthesis of spider silk is not viable at present due to the

lack of knowledge about silk structure so the replication of silk is currently

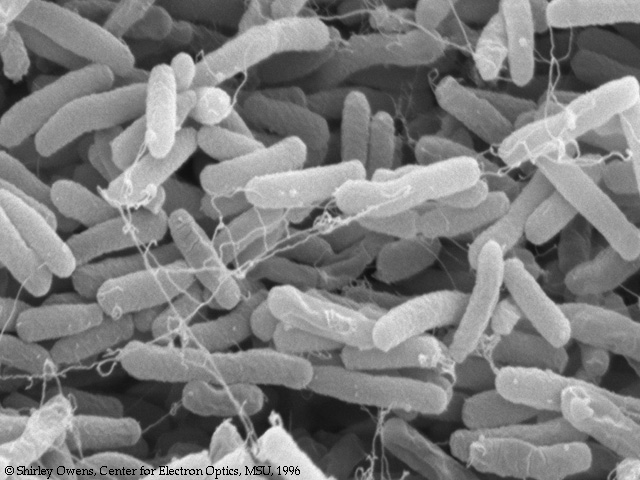

being achieved using genetic engineering. Randolph

V. Lewis, Professor of Molecular Biology at the University of Wyoming in

Laramie, has inserted silk genes into Escherichia coli bacteria to successfully

produce the repeated segments of spidroin 1 and spidroin 2.

The

alternative approach is to learn how spiders spin silk and then copy them to

make synthetic spider silk. The

silk itself would also have to be artificially made.

Chemical synthesis of spider silk is not viable at present due to the

lack of knowledge about silk structure so the replication of silk is currently

being achieved using genetic engineering. Randolph

V. Lewis, Professor of Molecular Biology at the University of Wyoming in

Laramie, has inserted silk genes into Escherichia coli bacteria to successfully

produce the repeated segments of spidroin 1 and spidroin 2.

More

recently, Nexia Biotechnologies Inc in Montreal, Canada have inserted silk genes

into goats to produce silk proteins in their milk.

This is hoped to be a better method because protein from bacteria is not

as strong due to faulty crosslinking of the proteins and hard white lumps can

form. Milk production in mammary

glands is similar to silk protein production in spiders so it is thought that

proper protein crosslinking could occur in goats.

More

recently, Nexia Biotechnologies Inc in Montreal, Canada have inserted silk genes

into goats to produce silk proteins in their milk.

This is hoped to be a better method because protein from bacteria is not

as strong due to faulty crosslinking of the proteins and hard white lumps can

form. Milk production in mammary

glands is similar to silk protein production in spiders so it is thought that

proper protein crosslinking could occur in goats.

It has been

suggested that the whole gene sequence might not be needed to produce useful

spider silk. Prospects include

possible gene insertion into fungi and soya plants.

It may also be possible to alter the silk genes for specific purposes.

For example altering the genes responsible for camouflaging spider silk

in nature could lead to a range of silk colours.

It has been

suggested that the whole gene sequence might not be needed to produce useful

spider silk. Prospects include

possible gene insertion into fungi and soya plants.

It may also be possible to alter the silk genes for specific purposes.

For example altering the genes responsible for camouflaging spider silk

in nature could lead to a range of silk colours.

Photograph by Carolyn Merchant

There are still problems with developing synthetic spider silk production. An artificial method of spinning silk remains a mystery. Spider spinning dope is approximately 50% protein but this is too high a concentration to use industrially since the fluid would be too viscous to allow efficient spinning. The silk is also insoluble in water but this can be overcome by attaching soluble amino acids such as histidine or arginine to the ends of the protein molecules. In addition, the silk coagulates if the fluid is stirred so it would have to be redissolved. Current research focuses around these problems and a possible solution would be to adapt the composition of silk proteins to alter its properties. Research is still in its early stages but unravelling the secrets of spider silk is underway.