Chapter 5

The Electrochemistry of Highly Doped Diamond Films

5.0 Outline

ˇ

This

chapter contains details of the apparatus used for the electrochemical

experiments in these studies.

ˇ

The

chapter describes the electrochemistry of highly doped diamond films. Cyclic

Voltammogams were recorded with a number of well known redox couples to show

the behaviour of the films.

ˇ

The

effect of surface termination of the electrode was investigated.

ˇ

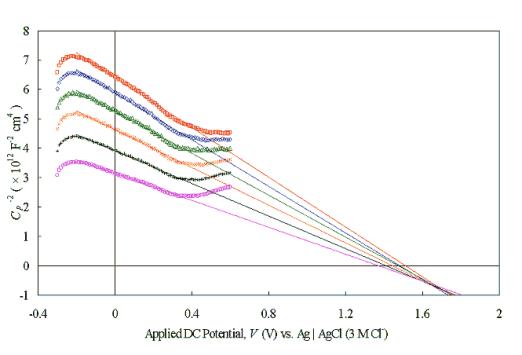

AC

Impedance and Mott-Schottky plots are presented.

ˇ

The

results of the electrochemical experiments are explained in terms of the theory

outlined in chapters 4 and 7.

5.1 Experimental Set-up

Electrochemical experiments

were performed using a three electrode system. This section describes the

apparatus used.

5.1.1 Electrolyte Solutions

Aqueous solutions were made

up with 18.3 MW cm ultrapure deionised water (Millipore).

Standard laboratory grade reagents were used to make up

the background electrolytes. Appendix A contains details of the stated maximum

levels of impurities.

Glassware was cleaned with a four

step process:

1.

soaking

in a base bath

[saturated sodium hydroxide (NaOH) in ethanol(C2H5OH)];

2.

immersing

and rinsing in deionised water;

3.

soaking

in an acid bath

[2.5 dm-3 nitric acid (HNO3) to 10 dm-3 water

(H2O)].

4.

immersing

and rinsing in deionised water.

Dissolved oxygen (O2)

was removed from the electrolyte solutions by purging the liquid with standard

laboratory grade oxygen-free nitrogen (N2) for at least 30 minutes.

5.1.2 Electrochemical Cells

The main type of cell used

in these studies was a single chamber design. A schematic diagram is shown in

figure 5.1. This cell design proved ideal for performing electrochemistry with

silver dag, TLM and TiUL contacts.

The electrochemical cells

were fabricated from white cylinders of PTFE

(50 mm in diameter). A central bore was removed from the main segment of

the cell to provide a reservoir for the electrolyte. The diamond sample that

was to be used as a working electrode (WE) was laid horizontally and sandwiched

between two PTFE cylinders. A 3mm hole in the base of the main piece and an O

ring (3 mm internal diameter) exposed a selected area of the electrode

surface to the electrolyte. Therefore, the approximate electrode area exposed

the electrolyte was 0.07 cm2 (7 mm2).

Figure 5.1 A schematic

diagram of an electrochemistry cell

The base of the cell was

tapered to allow small samples to be used. All samples had to be flat and the

minimum sample size was 15 mm ´ 5 mm. Typical sample

dimensions were 15 mm ´ 10 mm.

The bottom piece of PTFE was

attached to a brass plate to provide a stable base.

A transparent top piece was

fitted over the cell. The reference electrode (RE) and the counter electrode

(CE) were placed through holes in the top. They were held in place by rubber

rings (not illustrated in figure 5.1). Two additional holes allowed for

deoxygenating to be performed. Nitrogen could be bubbled through the

electrolyte via a needle that was passed down into the solution.

Control experiments could be

performed with platinum (Pt) working electrodes. Platinum wires could be passed

down through one of the gas holes.

Optical experiments were

performed by removing the lid of the vessel. The reference and counter

electrodes were then clamped in place and the sample was illuminated from

above, through a minimum depth of electrolyte.

Early experiments performed

with indium/gallium (In/Ga) eutectic contacts to the silicon substrate were

performed in a three compartment glass cell. The sample was attached to a steel

strip and covered with adhesive PTFE tape. This provided a temporary waterproof

cover over the electrode. A circular hole with a diameter of 5 mm was punched

into the PTFE tape so as to expose an area of approximately 80 mm2

of the electrode surface. This working electrode was placed in the central chamber.

A reference electrode was placed in a side compartment which was connected to

the central chamber through a Luggin capillary tip. A counter electrode was

placed in the other side compartment which was connected to the main chamber

through a glass frit.

5.1.3 Reference Electrodes

Silver | silver chloride

(Ag | AgCl) reference electrodes were used (BAS [Bioanalytical

Systems, Inc.] and CH Instruments, Inc.). These electrodes comprised of a

silver chloride coated silver wire in a glass tube with a porous polymer tip (Vycor frit). The glass tube formed an

electrode compartment which was filled with 3 mol dm-1 potassium

chloride (KCl) or sodium chloride (NaCl).

A diagram of a reference electrode is shown in figure 5.2.

The standard potential, E0, for the

Ag | AgCl redox couple at 25 ēC is

+ 0.22239 ą 0.00005 V relative to the normal hydrogen electrode (NHE). 127-128

The redox potential for the reference electrode, E, is dependant on the concentration of chloride ions in the

electrode compartment. The Nernst equation for the Ag|AgCl electrode can be

represented as:

![]() where g = activity coefficient for the solution

where g = activity coefficient for the solution

[Cl-] = concentration of Cl- ions

This gave a redox potential

for the reference electrode of + 0.194 V vs.

NHE at 25 ēC.

Figure 5.2 (top) A

schematic diagram of a Ag | AgCl reference electrode

(adapted from BAS sales

literature)

Figure 5.3 (bottom) A schematic diagram of a platinum counter electrode

5.1.4 Counter Electrodes

Platinum (Pt) counter

electrodes were made from a curled square of platinum mesh attached to a platinum

wire. This provided a suitably large surface area. A glass tube was used to

hold the electrode. This was designed with the same diameter as the reference

electrode. The tube was sealed to the platinum wire at the bottom of the

electrode. The top of the tube, which was never submersed into the electrolyte,

was left open. This allowed for repairs to be made to the electrode if the

seals or joins became damaged. Nickel wire was used inside the glass tube

because it was less expensive than the platinum wire. The wire was wound round

a notch at the top of the electrode, so that the weight of the attached

crocodile clip did not apply a force on to the platinum-nickel join or the

platinum-glass seal. A quick fit stopper was fitted to the top of the electrode

provide compatibility with a number of other designs of electrochemical cell. A

diagram of a counter electrode is shown in figure 5.3.

5.1.5 Potentiostats

Cyclic voltammograms were

recorded with a computer controlled E-Chemie m‑Autolab potentiostat.

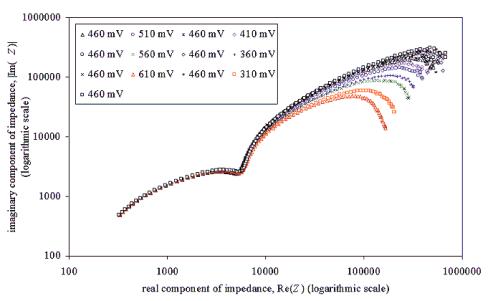

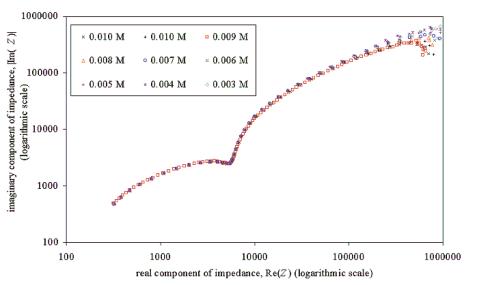

A Solartron 1286 potentiostat and a Solartron 1250

Frequency Response Analyser (FRA) were used to take AC impedance measurements.

The experiments were controlled and the results captured with the ZPlot/ZView

and CorrWare/CorrView software packages.

IMPS studies were performed

with the Solartron FRA and a potentiostat that was built in-house by the

electronics workshop. The in-house potentiostat was designed to prevent phase

shifting of the signal over a wide range of frequencies.

5.1.6 Faraday Cages

Experiments were performed

in Faraday Cages. The cages were fabricated in-house by the mechanical

workshop. They were welded together from sheet steel and painted black. The

boxes measured approximately 1 m (height) ´ 1 m (width) ´ 1 m (depth). The front panel incorporated a

large hinged door.

The Faraday Cages isolated

the experiments from electromagnetic interference and external sources of

light.

5.2 The Cyclic Voltammetry

Technique

Cyclic voltammetry is a

technique which can be used to study the electrode kinetics of a redox couple

in a three electrode system.

The potential of the working

electrode is swept between two set potentials. The scan rate (the magnitude of

the rate of change of the applied potential with time) is kept constant.

As the applied potential is

increased, oxidation will occur and a positive current will flow (electron

transfer from the species being oxidised to the electrode). Conversely, as the

potential is decreased, reduction will occur and a negative current will flow

(electron transfer form the electrode to the species being reduced).

5.2.1

Reversible Electrode

Dynamics

Reversible electrode

dynamics are exhibited in systems where the heterogeneous rate constants are

large. Reactions will start to occur as soon as the potential is such that they

are thermodynamically viable. As both the forward and back reactions are rapid,

the concentrations of the reduced and oxidised species will be effectively

maintained at the ratio predicted by the Nernst equation. The resulting cyclic

voltammogram will exhibit the following features. 120

ˇ

The

scans will be symmetrical.

ˇ

The

potentials at which the peaks occur will be independent of scan rate.

ˇ

The

peak separation will be approximately equal to (59 ´ n) mV

at 25 °C where n equals the

number of electrons transferred in the reaction.

ˇ

The

peak height will vary as the square root of the scan rate.

5.2.2 Irreversible Electrode

Dynamics

A system which exhibits

irreversible electrode dynamics will produce a cyclic voltammogram with

different characteristics to those produced by a reversible system.

The onset of the reaction

will not occur at potentials immediately beyond the equilibrium potential. An

appreciable overpotential will be required to induce the reaction as it is not

kinetically favourable.

As the overpotential is

increased, the homogeneous rate constant increases and the rate of reaction

will rise. This will be countered by the depletion of the reactant at the

surface of the electrode. The position of the peak maximum reflects the balance

between the increasing heterogeneous rate equation and the decrease in the

surface concentration of the reactant. The current is controlled by the

electrode kinetics up to the peak maximum. After the peak maximum, the current

simply reflects the rate at which the reactant diffuses though the solution to

the surface of the electrode.

Irreversible systems are not

kept at equilibrium and the back reaction is negligible.

A cyclic voltammogram for an

irreversible system will exhibit the following features. 120

ˇ

The

peak separation will be wider than the (59 ´ n) mV at 25 °C seen for reversible systems.

ˇ

The

peak separation will increase with scan rate.

ˇ

Irrespective

of the electrode dynamics, the peak height will vary as the square root of the

scan rate.

5.2.3 Quasi-Reversible

Electrode Dynamics

Reversible electrode

behaviour is the limiting case when the electrode kinetics are fast relative to

the mass transport conditions. Conversely, irreversible electrode behaviour is

the limiting case when the electrode kinetics are slow relative to the mass

transport conditions. Intermediate cases exist where the surface concentrations

of the reduced and oxidised species depend on both the electron transfer rates

(forward and reverse) and the rate of mass transport. These cases are said to

exhibit quasi-reversible behaviour.

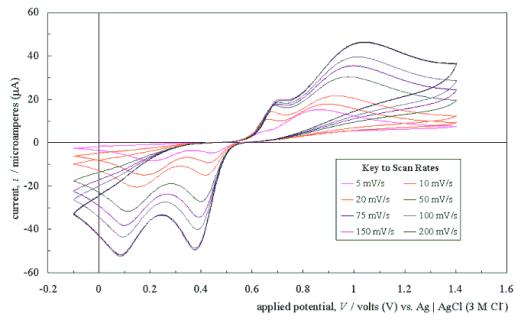

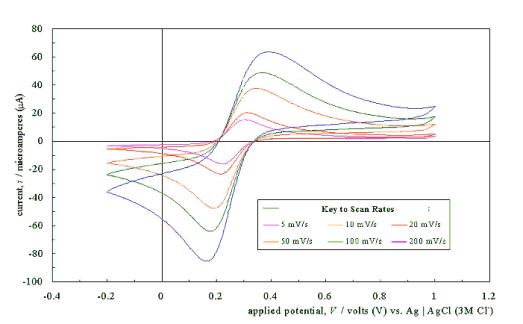

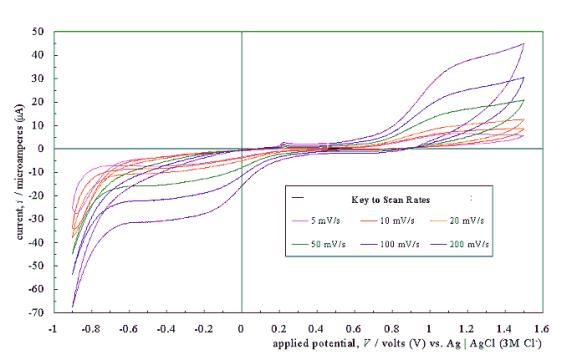

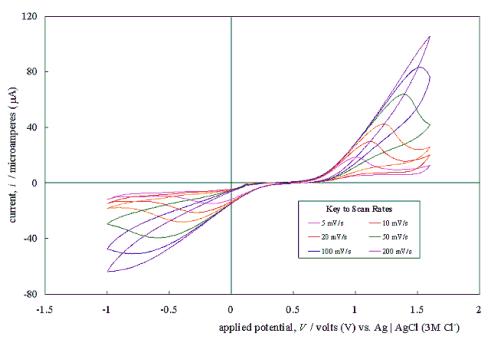

5.3 Cyclic Voltammetry in

Dilute Nitric Acid

Cyclic voltammograms were

recorded in an aqueous solution containing 1 mol dm-3 nitric acid (HNO3) and 2 mol

dm-3 sodium chloride (NaCl).

A highly doped diamond film

used as a working electrode (sample B67, doping level 5 ´ 1021 cm-3, silver dag

contact). Before use, the diamond

film was refluxed in concentrated nitric acid in order to reduce the presence

of any non-diamond carbon. Electrical contacts were then made to the top of the

film using silver dag.

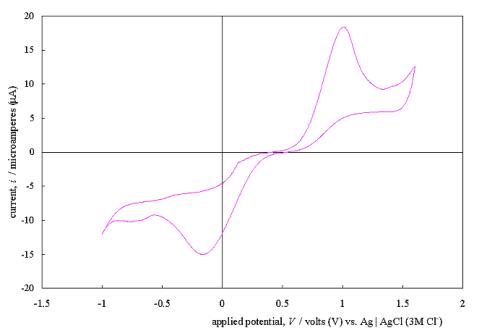

Figure 5.4 shows a typical

cyclic voltammogram recorded at a scan rate of 50 mVs-1. The

scan shows that the electrode has a wide potential window, with no significant

solvent breakdown occurring in a range from 0.7 V to 1.1 V with respect to the

Ag | AgCl (3 M Cl-) reference electrode. This window was

significantly wider than those reported for many commonly used electrode

materials.