Ammonia

This web site

aims to provide a full and comprehensive insight into ammonia production and

its history. Covered in this site are the following:

-

A brief insight into the chemistry

of ammonia. -

So how did the Haber-Bosch process

come about? -

So what is the Haber-Bosch

process? -

Why is ammonia so important? -

Other useful information.

A brief insight into the chemistry of ammonia:

Ammonia has a

triangular pyramidal geometry, and boiling points of 77.7*C and 33.5*C. In its

pure form ammonia was prepared in 1774 by Joseph Priestly, and its composition

was determined in 1785 by Claude-Louis Berthollet. Ammonia has a chemical

formula of NH3, and is sp3 hybridised. Ammonia is highly

polarised, due to the electronegativity of nitrogen, and as a result, has a

large dipole moment. Ammonia

NH3 (aq)

+ H2O (l) Û NH4 (aq) + OH (aq)

Ammonia

solutions are basic, due to the hydroxide ions formed in solution.

Ammonia

is commercially produced by the Haber-Bosch process, which is also sometimes

referred to as the

Left: Fritz Haber, 12.9.1868 - 29.1.1934. Right: Carl Bosch, 27.8.1874 Both images taken without consent from

So how did the Haber-Bosch

process come about?

At

the end of the 19th century, Chilean nitrates, were the major source

of nitrates at the time. It was clear, that this source would not be able to

meet future demands. It was also realised that in the event of a war, any

nation cut off from the Chilean supply, would not be able to make adequate

amounts of munitions. Germany (Haber

So what is the Haber-Bosch process?

The

production of ammonia is achieved by the direct combination of hydrogen and

nitrogen, over an iron or aluminium catalyst. Hydrogen is obtained from the

decomposition of methane by heating. Nitrogen is obtained from the distillation

of liquefied air. It was the first chemical process to use high-pressure

conditions. The reaction is shown below:

N2(g)

+ 3H2(g) Û 2NH3(g)

The

process is highly exothermic with a ÙH value of

(LeChetelier

Catalyst:

The catalyst

provides an alternative pathway for the reaction to occur, which has lower

activation energy. This means that a lower temperature can be used without

compensating the rate too much. Carl Bosch found that a mixture of Fe2O3 and Fe3O4

catalyses the reaction best over the temperature range 650

Pressure:

Also due to

LeChetelier

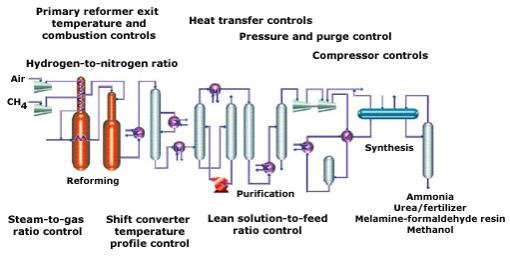

Below is a

diagram of a modern ammonia production site:

Taken from

What is ammonia used for?

Ammonia is a very useful product indeed. There are many, many uses for

ammonia and it

More information on

ammonia related subjects:

http://www.Foxboro.com/industries/ammonia

http://www.analyticpower.com/NH3CRACK.html

Some useful information:

Click here to link to my home

page

Click here if you wish to e-mail

me