In The Past

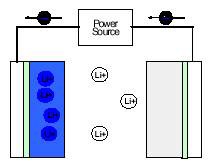

In the second type, two complementary electrochromic molecules are dissolved in a solvent. This type of system is very simple to build, reacts very fast and can produce dark or bright colors. The drawback of this type is that an electrical current is needed to maintain the colored state because the two types of colored molecules diffuse through the

Problem and solution

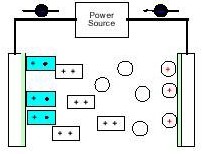

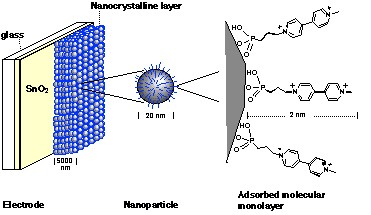

We therefore need a system which is both bistable and changes colour rapidly. This can be done by attaching a suitable molecule that is colourless in the oxidized state and coloured in the reduced state onto the surface of a colourless semiconductor on conducting glass. When a sufficiently negative potential is applied, electrons are injected from the conducting glass into the conduction band of the semiconductor and reduce the adsorbed molecules. The reverse process occurs when a positive potential is applied and the molecules get bleached. The advantage of this system is that combines immobility of the electrochromic material with the rapidity and coloration efficiency of molecular systems.

However, a single molecular monolayer does not absorb a perceptible amount of light. This is where nanoparticles come in!

Nanocrystalline amplification

By using nanocrystalline semiconductor films, it was possible to amplify the light absorption of the molecular monolayer to obtain visible color changes. The nanocrystalline layer are highly porous and usually the real surface of a 5 Ám thick layer is about 500 times the projected area. Therefore, as light passes through the layer, it crosses several hundreds of monolayers of coloured molecules giving a strong absorption.

Principle of the nanocrystalline

amplification. The highly porous nanocrystalline layer of the

semiconducting material allows more absorbed molecular monolayer to be

present. Hence increasing the absorption of light.

Product

Some commercial products has already been produced!

|

The most successful is the automatic dimming rear-view mirror sense ambient light and glare from behind, and reduce annoying glare from bright lights. |

|

|

|

|

The picture on the right and below show examples of the paper quality displays from NTera |

|