The future of solar cells

Recently there have been many developments in solar cell technology which have the potential for great improvements in efficiency and cost. Some of these new advances are outlined below:

The use of dyes

Researchers in America have recently discovered a new type of device for use in solar cells. Researchers at the University of California at Santa Barbara have made a multi-layer cell which collects photons using dye molecules placed on a gold film surface which rests on a layer of semi-conducting titanium dioxide. The excited electrons from the dye are first transferred to the gold film and then to the semi-conductor material. This method has the advantage that an especially large number of photons are absorbed by the dye layer (about 10%). The principle of the device is also based only on the movement of electrons, which makes it much less sensitive to impurities. The team now hopes to further increase the internal quantum efficiency and go on to make a new type of cell which will be a low cost alternative to the traditional silicon cell.

Image taken from http://physicsweb.org without permission

Microstructure substrates

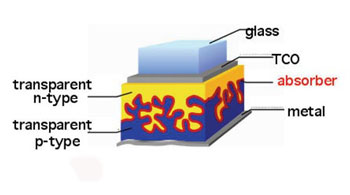

Most commercial cells use flat substrates onto which an absorbing layer is deposited. A new device however, produced by researchers at the Hahn Meitner Institute in Germany has a cadmium tellurium absorber layer deposited on top of a microstructured substrate made from titanium dioxide. When photons arrive at the absorber layer, they excite electrons into the conduction band and any stray photons are scattered back into the layer by the titanium dioxide.

Image taken from http://physicsweb.org without permission

This creates an output current which is as much as fifty times greater than what would be expected from a cell with a normal flat substrate. The structure of the absorber layer shortens the excited electron's path length which means lower quality material can be used. The scattering causes the light path to be enhanced which means more light is absorbed do less material can be used. An absorber layer 150-200nm thick was enough to give a voltage of 0.67V (the kind of value expected from a traditional cell).

Full Spectrum Solar Cells

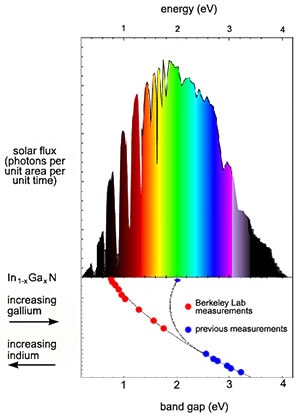

One of the major limitations of solar cells is the band gap of the semi-conductor which is used to make the cell. The band gap determines which photons are absorbed. Photons with too little energy will go straight through and photons with too much energy will be absorbed but the excess energy will be wasted as heat. Researchers at Lawrence Berkeley National Laboratory found out that indium nitride has a band gap of 0.7eV (not 2eV as previously thought). This meant that an alloy which contains indium, gallium and nitrogen can convert virtually the full spectrum of sunlight to electrical current.

Image taken from www.lbl.gov without permission

Solar cells have not yet been made with this material, but the potential is there for inexpensive cells which are the most efficient ever created. The alloy is highly resistant to imperfections and could be stacked in many layers to achieve very high levels of efficiency.

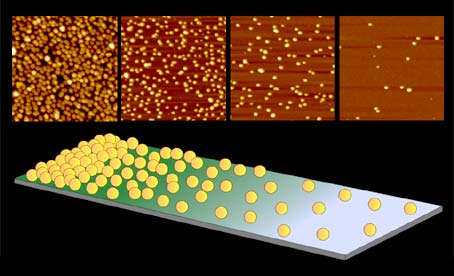

Nanoparticles

Nanoparticles are very small particles which exhibit the interesting characteristic that their band gap can be changed by changing their size. This gives the potential to create nanoparticles which absorb all visible light and nothing else. As the particles are so small, it is impossible to hardwire them so a electrolyte is also needed. Researchers at Kansas State University have been doing research into gallium selenide and indium selenide particles. There is still a long way to go before efficient solar cells can be made with these particles. This is partly due to the difficulties of making and working with them, and also because the science behind their properties is still poorly understood. Nanoparticles also eliminate the problem of impurities. If a cell is made with nanoparticles, the few particles with impurities will not function but all the others will and the overall cell will not be affected.

Image taken from www.globaltechnoscan.com without permission