| |

Making your own Superconductors

|

|

With the advent of high temperature superconduction, it is relatively

simple to prepare and use a ceramic high temperature superconductor

in most sixth form/college science labs.

What follows are brief instructions for making an yttrium-barium-copper-oxide

superconductor - these are taken from the instructions provided

with a superconductor fabrication kit that was marketed by Colorado

Futurescience; Colorado Futurescience no longer make this kit, and

so made the instructions available on the web at http://www.webcom.com/cfsc/scpart1.html.

The method is typical of ceramic processes in scientific research.

This obviously means that these instructions are reproduced here

for purposes of interest, and I can't accept any responsibility

for their use.

For other instructions and commercial superconductor kits, check

out the 'Play' section

at Superconductors.org, which has links manufacturers and retailers.

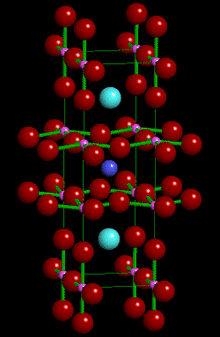

Left: Crystal structure of YBa2Cu3O7

- the so-called "1-2-3" superconductor. Click to open

a 3D VRML structure which you can rotate around.

(You will need a suitable VRML plugin

for this - the latest is SGI's Cosmo Player available at http://www.cosmosoftware.com/download)

|

Equipment

To make an yttrium-barium-copper-oxide superconductor, you will need:

Method

There are a number of methods of producing ceramic superconductors like

this, but the simplest is the so-called "shake and bake" method,

which involves a four step process:

-

Mixing the chemicals;

-

Calcination(the initial firing);

-

The intermediate firing(s) (oxygen annealings);

-

The final oxygen annealing.

The number of intermediate firings and the length of the firings are

largely up to the user. In general, the more intermediate firings, and

the longer the duration of the firings under oxygen flow, the better the

superconductor. But definite signs of superconductivity can usually be

obtained without any intermediate firing at all. In fact, if the initial

mixing of the chemicals is sufficiently thorough, the intermediate firing

is not necessary at all.

-

1. Mixing the chemicals

-

The starting mix is a grey powder made by thoroughly mixing yttrium

oxide, barium carbonate and cuprix oxide in the ratios 1:2:3 (This

superconductor is often referred to as "1-2-3" as a result)

-

-

- Yttrium Oxide, Y2O3 - 11.29 grams

- Barium Carbonate, BaCO3 - 39.47 grams

- Cupric Oxide, CuO - 23.86 grams

-

2. Calcination

- For the initial heat treatment, called calcination, the mix is heated

at 925-950 degrees Celsius for about 18-24 hours. This first treatment

may be done in a crucible or evaporating dish made of alumina or of

a good grade of laboratory porcelain. This forms the basic crystal structure

of YBa2Cu3O6.5, and gets rid of the

carbon dioxide from the barium carbonate. (Barium carbonate is used

instead of barium oxide because barium oxide of any reasonable purity

is difficult to obtain. Also, exposing barium oxide to air tends to

quickly convert much of it to barium carbonate and barium hydroxide.)

The result of this first firing is a porous black or very dark gray

clump. The coloration should be fairly even. An uneven green coloration

is an indication that the powders are not as thoroughly mixed as they

should have been, and that extra time and care should be taken to insure

thorough grinding and mixing on subsequent steps. The material will

seem to shrink rather dramatically during the initial firing as it loses

its carbon dioxide and becomes much denser than the original powder

mix.

-

3. Intermediate firing(s)

-

The porous black clump is ground into a fine powder and placed in

the furnace in an alumina dish. After the furnace temperature reaches

about 500 degrees Celsius, begin a slow flow of oxygen into the furnace.

This heat treatment under oxygen flow is called oxygen annealing.

A final furnace temperature of 925 to 975 degrees Celsius is recommended

for the intermediate firings. A temperature much higher than this

will result in a material that is much harder to re-grind. Temperatures

above 1030 degrees Celsius may destroy the crystal structure.

After the mix has heated in the furnace for at least 18 hours at

925-975 degrees Celsius, reduce the temperature slowly. If you plan

to test the sample for superconductivity after this firing, the cooling

rate must be no more than 100 degrees per hour until 400 degrees Celsius

is reached. The rate of cooling from 400 degrees down to room temperature

can be increased to about 200 degrees per hour. If you do not plan

to test for superconductivity after this firing, a cooling rate in

excess of 100 degrees per hour may be used; however a cooling rate

in excess of 250 degrees per hour is not recommended. Do not remove

the oxygen flow until the indicated furnace temperature has fallen

below 400 degrees Celsius.

The material should be thoroughly re-ground in a mortar and pestle

(or similar device) between each firing. (If, after an intermediate

firing, there is some green coloration in the resultant disk, it is

important to take extra time and care in re-grinding and mixing the

material before the next firing.) Problems that occur in the mixing

and grinding process in any of these steps are often due to hard,

coarse particles being mixed in with the finely powder material. An

ordinary kitchen tea strainer can come in handy at this point to separate

the coarser particles or lumps so they may be ground separately. IMPORTANT:

If you an ordinary tea strainer, make sure it is made of a non-magnetic

material, or make sure you are satisfied that none of the material

in the sifter or strainer will contaminate the chemicals. Even very

small quantities of magnetic materials in the chemical mix can diminish

or destroy the potential superconductivity. (It is also for this reason

that "ceramic grade" chemicals, which tend to have iron impurities,

are not often usable for making superconductors.) Shortcuts in grinding

the materials, such as using an electric coffee grinder, often contaminate

the compound with elements that destroy the superconducting properties.

Some contaminates will destroy superconductivity in very tiny amounts.

To keep your chances of success high, grinding with a good-quality

mortar and pestle is the best method. This manual grinding can be

an arduous process, but the results are worth the trouble.

-

4. The final oxygen annealing

-

The sample should be thoroughly reground, and the resultant black

powder placed back in the alumina dish. The thickness of the layer

of loose powder in the dish should match the desired thickness of

the final superconducting disk. For this final firing, the powder

should be as finely-ground and as densely-packed as possible. Do NOT

pack the powder into the dish by pressing on it from the top (as this

can makes the superconductor tend to stick to the alumina dish). Better

results can usually be obtained by tapping the alumina dish with a

pestle or a similar object so that the particles of the mix settle

together in an evenly packed disk.

For this final heat treatment, heat the sample to between 950 degrees

and 1000 degrees Celsius for about 18 hours. The higher temperature

is better, but be sure of the accuracy of your temperature indicator

before getting too close to 1000 degrees. Temperatures above 1020

degrees risk decomposition of the crystal structure and the possiblity

of the material sticking to the alumina dish. On the other hand, a

final oxygen annealing at only 950 degrees Celsius will yield a superconductor

that will crack easily, but will otherwise be satisfactory.

It is absolutely necessary that the cool-down take place very slowly

and under adequate oxygen flow. The rate of cooling must be no more

than 100 degrees Celsius per hour, especially during the critical

temperature region between 750 and 400 degrees Celsius. Take special

care to insure that the sample has access to plenty of oxygen, especially

in during the cool-down from 900 to 300 degrees. Brief interruptions

in oxygen flow when the material is above 900 are unimportant, but

continuous flow must be maintained during cool-down. If the atmosphere

in the furnace is not oxygen-rich while the sample is still above

about 400 degrees, the material can lose vital oxygen from its crystal

structure. After the furnace temperature reaches about 500 degrees,

the rate of cooling can be increased.

During this final heat treatment, a superconductor that is more

resistant to cracking during thermal stress can be produced by subjecting

the sample to high-temperature thermal cycling. To do this, vary the

temperature between 750 and 1000 degrees at rates of change of about

200 per hour. Then raise the temperature to about 1000 degrees for

an hour or more before beginning the final slow cool-down. This thermal

cycling is not a necessity at all, but it will add significantly to

the mechanical strength of the sample.

Testing the superconductor

The most foolproof test for superconductivity is the simplest. This is

the test for diamagnetism using small rare earth magnets made of samarium-cobalt

or neodymium-iron-boron, as seen in the QuickTime

video on the What Is Superconductivity?

page. Use a very small rare-earth magnet at first. Start with a rare-earth

disk magnet about 6 mm. in diameter. If you have made a good-quality superconductor,

the magnet will levitiate at least 3 mm. above the surface of the superconducting

disk. A superconductor with poor levitation can usually be improved by

re-grinding it and giving it an additional oxygen annealing.

When a superconductor levitates a magnet, a magnetic mirror image is

formed in the superconductor of the levitating magnet due to the exclusion

of the magnetic field (the Meissner

effect). The magnetic mirror image insures that there is always a

north pole induced in the superconductor directly below the north pole

of the levitating magnet. There is a south pole induced in the superconductor

directly below the south pole of the levitating magnet. This mirror image

moves with the magnet as the magnet is moves, so that the disk magnet

can be given a rapid spin without affecting its levitation. In fact the

magnet may continue to spin for quite a long time because its spinning

encounters no friction other than the friction of air resistance.

|