|

Origins

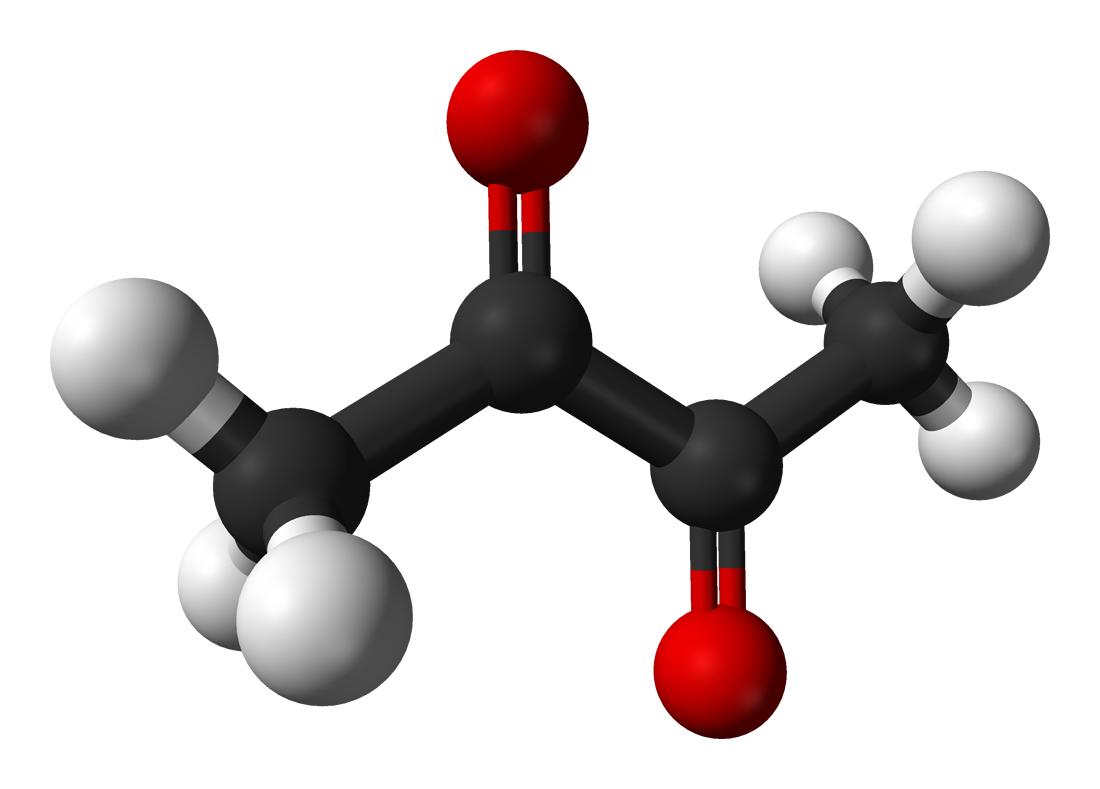

It

was discovered by world-reknowned, French scientist Louis Pasteur in

the 1860s through his research on the fermentation of beer and ale. He

determined yeast was alive and actively reproduced. He learned the

compound, now referred to as diacetyl, is naturally produced through the

fermentation process.

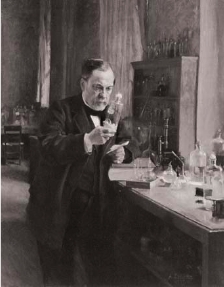

Pasteur

at work in his laboratory, a painting by Albert Edelfelt in 1885.

European

chemists later synthesized diacetyl from methyl ethyl ketone in

the 1920s and shortly after, artificial-butter flavoring spread rapidly.

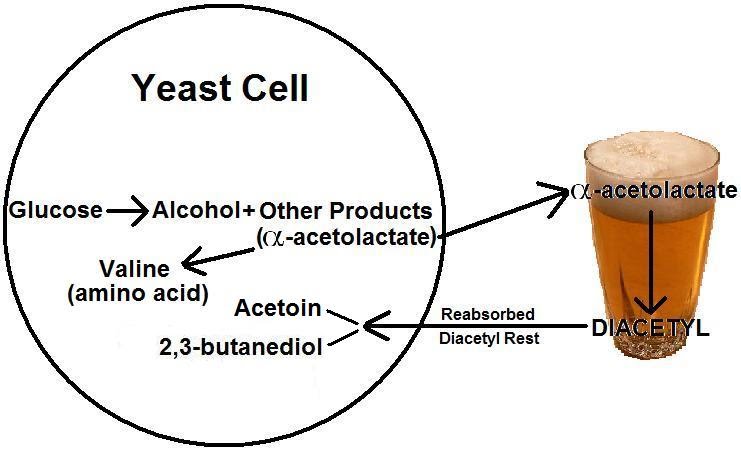

Role of Diacetyl in Brewing Yeast

are single-celled microorganisms that reproduce by budding. In beer,

they are responsible for converting sugar into alcohol, as well as other

by-products. It is this conversion that provides the main source of

diacetyl in beer. Outside of alcohol and carbon dioxide, many

other products occur from this conversion including the ester, α-acetolactate. Some of

this ester is used by the cell to produce the amino acid

valine, but most is dumped into your beer. Oxygen

and high temperatures help transform this into diacetyl. The

amount of diacetyl wanted varies from the type of beverage being brewed

and if taken, the next step helps determine this. After

fermentation, the yeast will reabsorb as much or as little diacetyl

intended. Often this is referred to as a "diacetyl rest," in

which high temperatures, and allowing the beer to remain in the

fermenter after fermentation, will cause the yeast to reabsorb

excess diacetyl and break it down.

At

low levels, diacetyl contributes a "slickness" on the tongue. As

the amount increases, it helps give a buttery or butterscotch taste to

the beer. Finding the proper medium is essential in creating the most

desirable beverage.

|

Originates from Beer |