CVD Diamond - a New Technology for the Future?

CVD Diamond - a New Technology for the Future?

Diamond has long held a special place in the hearts and minds both of scientists and the public at large. For some, the word diamond conjures up images of brilliant gem stones, wealth and special occasions. To the scientist, diamond is impressive because of its wide range of extreme properties. As Table 1 shows, by most measures diamond is 'the biggest and best'; it is the hardest known material, has the lowest coefficient of thermal expansion, is chemically inert and wear resistant, offers low friction, has high thermal conductivity, is electrically insulating and optically transparent from the ultra-violet (UV) to the far infrared (IR). Given these many notable properties, it should come as no surprise to learn that diamond already finds use in many diverse applications including, of course, its use as a precious gem, but also as a heat sink, as an abrasive, and as inserts and/or wear-resistant coatings for cutting tools. Obviously, given its many unique properties it is possible to envisage many other potential applications for diamond as an engineering material, but progress in implementing many such ideas was hampered for many years by the comparative scarcity of natural diamond. Hence, the long running quest for routes to synthesise diamond in the laboratory. So called 'industrial diamond' has been synthesised commercially for over 30 years using high-pressure high-temperature (HPHT) techniques, in which diamond is crystallised from metal solvated carbon at pressures ~50-100 kbar and temperatures ~1800-2300 K.

Diamond has long held a special place in the hearts and minds both of scientists and the public at large. For some, the word diamond conjures up images of brilliant gem stones, wealth and special occasions. To the scientist, diamond is impressive because of its wide range of extreme properties. As Table 1 shows, by most measures diamond is 'the biggest and best'; it is the hardest known material, has the lowest coefficient of thermal expansion, is chemically inert and wear resistant, offers low friction, has high thermal conductivity, is electrically insulating and optically transparent from the ultra-violet (UV) to the far infrared (IR). Given these many notable properties, it should come as no surprise to learn that diamond already finds use in many diverse applications including, of course, its use as a precious gem, but also as a heat sink, as an abrasive, and as inserts and/or wear-resistant coatings for cutting tools. Obviously, given its many unique properties it is possible to envisage many other potential applications for diamond as an engineering material, but progress in implementing many such ideas was hampered for many years by the comparative scarcity of natural diamond. Hence, the long running quest for routes to synthesise diamond in the laboratory. So called 'industrial diamond' has been synthesised commercially for over 30 years using high-pressure high-temperature (HPHT) techniques, in which diamond is crystallised from metal solvated carbon at pressures ~50-100 kbar and temperatures ~1800-2300 K.

Table 1: Some of the outstanding properties of diamond

- Extreme mechanical hardness (~90 GPa).

- Strongest known material, highest bulk modulus (1.2 × 1012 N/m2), lowest compressibility (8.3 × 10-13 m2/ N).

- Highest known value of thermal conductivity at room temperature (2 x 103 W / m / K).

- Thermal expansion coefficient at room temperature (0.8 × 10-6 K) is extremely low, comparable with that of invar.

- Broad optical transparency from the deep UV to the far IR region of the electromagnetic spectrum.

- Good electrical insulator (room temperature resistivity is ~1016 Ω cm).

- Diamond can be doped to change its resistivity over the range 10-106 Ω cm, so becoming a semiconductor with a wide bad gap of 5.4 eV.

- Very resistant to chemical corrosion.

- Biologically compatible.

- Exhibits low or 'negative' electron affinity.

World interest in diamond has been further increased by the discovery in the late 1980s that it is possible to produce polycrystalline diamond films, or coatings, by a wide variety of chemical vapour deposition (CVD) techniques using, as process gases, nothing more exotic than a hydrocarbon gas (typically methane) in an excess of hydrogen. This CVD diamond can show mechanical, tribological, and even electronic properties comparable to those of natural diamond. Nowadays, large single-crystal diamonds of gemstone quality can be fabricated by CVD, and this has led to so-called lab-grown diamonds flooding the jewellery market at much cheaper prices than mined natural diamonds.

For scientists and engineers, however, the ability to make diamond in the form of thin films or coatings means that all the extreme properties of diamond given in Table 1 can now be exploited to provide an astonishing range of applications.

|

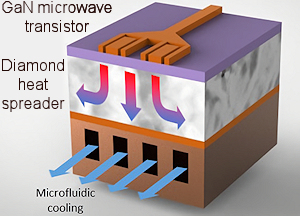

Thermal management - Natural diamond has a thermal conductivity roughly four times superior to that of copper, and it is an electrical insulator: It should therefore come as little surprise to learn that CVD diamond is now being marketed as a heat sink for laser diodes and for small microwave integrated circuits. The natural extrapolation of this use in circuit fabrication ought to be higher speed operation, since active devices mounted on diamond can be packed more tightly without overheating. One application is to use diamond to cool the GaN devices used in mobile-phone base-station transmitters for 5G and next-gen networks. |

|

Cutting tools - CVD diamond is also finding applications as an abrasive and as a coating on cutting tool inserts. CVD diamond-coated drill bits, reamers, countersinks, etc. are now commercially available for machining non-ferrous metals, plastics, and composite materials. Initial tests indicate that such CVD diamond-coated tools have a longer life, cut faster and provide a better finish than conventional tungsten carbide tool bits. |

|

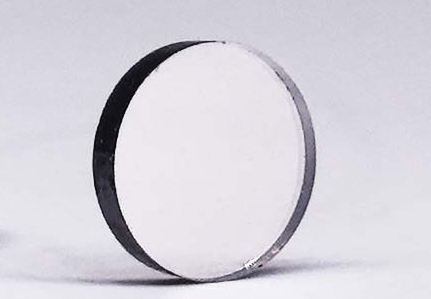

Optics - Because of its optical properties, diamond is beginning to find uses in optical components, particularly as protective coatings for infrared (IR) optics in harsh environments. Most IR windows currently in use are made from materials such as ZnS, ZnSe, and Ge, which, whilst having excellent IR transmission characteristics, suffer the disadvantage of being brittle and easily damaged. A thin protective barrier of CVD diamond may provide the answer. Some IR windows are now beig made from free-standing diamond films grown to a thickness of a few mm using improved high growth-rate techniques. |

|

Electronic devices - the possibility of doping diamond and so changing it from being an insulator into a semiconductor opens up a whole range of potential electronic applications. Despite difficulties with doping, CVD diamond-based devices are gradually beginning to appear, such as Schottky diodes, radiation detectors, and even field effect transistors. The main advantage that diamond has over other semiconductors, such as Si, is that diamond devices should be able to opeate at higher temperatures and higher frequencies, which means higher power levels for power devices. |

|

Electrochemistry - highly boron-doped diamond is conducting, and can be used as an electrode in an electrochemical cell. Such diamond electrodes have a number of major advantages over conventional electrodes, such as a wider operating voltage, higher sensitivy, less fouling, etc. They can also be used to clean up contaminated water supplies, such as rivers or reservoirs, by passing high crrents through the water to fragment toxins or biological hazards. |

|

Quantum computing - there are anumber of defetcs in diamond, most notably the NV defect, that can function as single-photon emitters. The individual photons that are emitted from different defect centres can be captured and combined inside a light-pipe causing quantum entanglement of their wavefunctions. This can lead to qbits, and quantum computers that would operate at millions of times the speed of normal binary computers. |

|

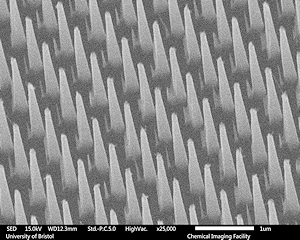

Electron emission devices - the layer of atoms on a diamond surface can be chemically changed to impart what's known as negative electron affinity. This means that very little energy is required to persuade bulk electrons to emit from the diamond surface. This can be used to make thermionic energy converters for solar power generation, field emssion devices for flat-panel displays, or secondary electron multipliers for photomultiplier tubes or night-vision goggles. |

|

Neural implants - diamond is biocompatible, which means that when it is implanted into the human body it does not provoke an immune response or cause inflamation or scarring. It is possible to make conducting boron-doped diamond sensors that can be embedded into the central nervous system or brain of a patient and interact with the nerve signals. Such implants can remain in place for decades, longer than the lifetime of the patient. The signals from the neurons can be read-out and interpreted by software, enabling brain-computer interfaces and the possibility of thought-controlled electronics. Alternatively, signals can be passed into the nerves to treat diseases like Parkinsons', or to bridge breaks in the spinal cord, allowing functionality to return to paralysed limbs. |

These are only a small selection of some of the astoishing applications that CVD diamond promises in the next 10-30 years. There is a huge amount of work being done throughout the world, and in the Bristol lab, to bring these ideas to fruition, and progress is being made seemingly on a daily basis. If this continues, the future for CVD diamond looks bright indeed.

Further Reading

A more detailed review of the subject of CVD diamond, including many of the source references can be found our review articles:

- P.W. May, "Diamond Thin Films: A 21st Century Material" Phil. Trans. R. Soc. Lond. A, 358 (2000) 473-495.

- P.W. May, R. Zulkharnay, "Diamond Thin Films: A 21st Century Material. Part 2: A New Hope", Phil. Trans. Roy. Soc. Lond. A 383, (2025) 20230382. [doi: 10.1098/rsta.2023-0382].

- R. Zulkharnay, P.W. May, "Applications of Diamond Films: A Review", Funct. Diamond 4, (2024) 2410160. [doi: 10.1080/26941112.2024.2410160]