Production of Diamond Films using a DC Plasma Reactor

Production of Diamond Films using a DC Plasma Reactor

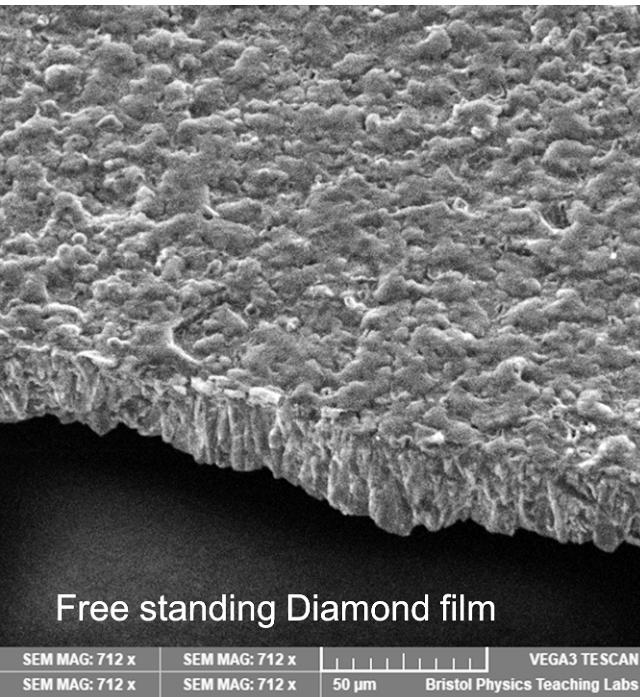

The aim of this project was to build a reactor that could deposit high-quality polycrystalline diamond films over large areas (6" wafers). This is tricky to do in microwave plasma reactors due to the need for a tuned cavity, so we opted to build a DC reactor which does not suffer from this issue. However, DC plasmas can cause high-energy ion bombardment of the growing diamond surface, which would damage the diamond lattice and cause poorer quality films, such as UNCD, NCD or even DLC fims, to be deposited instead. This can be avoided if a high process pressure (300+ Torr) is used such that the neutral gas molecules scatter the high-energy ions so they lose much of their energy and directionality (i.e. thermalise) before they strike the surface.

We named the DC reactor 'The Minion' (for obvious reasons), and it successfully deposits diamond at rates of ~10 μm h-1, but only over areas around 1" diameter. For areas larger than this, arcing becomes a problem because the two electrodes only need to be out of parallel by a fraction of a mm for the plasma to prefer to arc across this gap than form a stable large pancake plasma. Nevertheless, we have managed to use this reactor to deposit a thick diamond coating on 12 WC drill bits simultaneously.

Work is still ongoing to try to improve the deposition area and uniformity.

|

.jpg) |

|

|

| The 'Minion' DC plasma reactor | Standing wave ripples in the DC plasma | Diamond-coated drillbit | Diamond film deposited in the Minion |